Flow control for pulp, paper, board and tissue

Valves and flow control play a vital part in pulp, paper, board and tissue production. The rapidly evolving industry is being reinvented to help create profitable and sustainable success. Through progressive thinking, creative design and solid manufacturing expertise, we are helping drive increasingly intelligent processes towards improved efficiency, reliability and environmental performance. Valmet has been a pioneer in the paper business since the very beginning, which is why today most of the world’s pulp flows through our valves.

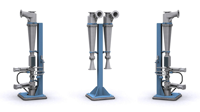

Pulp