VII for Production Capacity

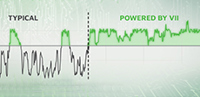

Solution enables maximization of fuel power of the most cost efficient plant, based on real-time information of the production capacity utilizing process bottlenecks.

Energy

VII for Production Capacity

Solution enables maximization of fuel power of the most cost efficient plant, based on real-time information of the production capacity utilizing process bottlenecks.

Energy

Decarbonizing with technology

How can the making of pulp and paper become carbon neutral? In this episode, Pirita Mikkanen, Vice-President of Energy at Metsä, and Janne Pynnönen, Head of R&D at Valmet, discuss when and how this can become a reality: What is the role of technology in reducing emissions and what kind of technologies will enable such reductions even more in the future.

Insights ● Podcast

Gap for board

OptiFormer Gap forming section with roll and blade technology is an optimal concept for lightweight recycled fiber-based fluting and linerboard for high-speed applications.

Board and paper

OptiAir Environment

OptiAir Environment consists of environmental emission control systems for creating a healthy and comfortable mill environment.

Board and paper

Rebuild concept improves the performance of Laakirchen Papier’s PM10

Laakirchen Papier was looking for ways to improve the web stability of their PM10 machine and to prepare it for future production increases. Thanks to Valmet’s rebuild concept, they were quickly able to achieve their target to increase production speed.

Insights ● Article

Board and Paper Newsletter

Subscribe to Valmet's Board and Paper Newsletter.

Insights

Process upgrades

Process upgrades are small or mid-size investments that opens up production bottlenecks or extends the original process design limitations.This is a cost effective way to reach new production targets or to lower the maintenance costs.

Services

Process parts

Valmet has developed superior process parts concepts for board and paper mills. Through innovations, continuous development and deep cooperation with our customers, we have developed solutions that save energy, chemicals and raw materials, while delivering performance in product lifetime, end-product quality, availability and productivity.

Services

Seinäjoen Energia: important milestones and handover around the corner

A new boiler plant for district heat production to Seinäjoen Energia Oy’s Kapernaum heat plant in Seinäjoki, Finland is taking significant steps forward in producing carbon neutral district heat.

Insights ● Article

Pellet plants

A pellet-fired plant represents an environmentally friendly solution to balance peak loads in district heating, to act as a backup plant or to generate process steam. Valmet offers turnkey pellet plants, ranging typically from 20 to 200 MWth for district heating and process industry needs.

Energy