Saica’s PM 11 breaking records from the kick-off

Valmet’s OptiConcept containerboard machine in UK is breaking world speed records from the beginning and production started 15 days earlier than originally planned.

Insights ● Article

Saica’s PM 11 breaking records from the kick-off

Valmet’s OptiConcept containerboard machine in UK is breaking world speed records from the beginning and production started 15 days earlier than originally planned.

Insights ● Article

Nine days without a break

A recent machine screen rebuild in Sweden achieves incredible results with paper quality and machine runnability. “No problems have occurred with screening since start-up,” says Öistein Vedahl, Production Manager of Lessebo Bruk.

Insights ● ArticleValmet’s CO2 reduction targets recognized for supporting UN climate change agenda in Paris

“We continuously work to make improvements which is seen in the favorable trend in our environmental KPIs: in 2014 we decreased our energy consumption by 9% and CO2 emissions by 16%,” says Victoria Larsson, Valmet’s Global HSE Manager

Insights ● Article

Workshop and roll services

How does your business sound like? Hopefully, there are no roll related vibrations, annoying production breaks or disturbing shutdowns. Valmet Workshop and Roll Services offer a winning combination of the latest roll technology and maintenance expertise. We help you eliminate unplanned shutdowns, increase the running times of rolls, improve the tissue quality and lower the roll maintenance costs in long-term.

Services

Advantage Yankee dryers

Lessons of the past for a high performing future - explore Valmet's Yankee dryers

Insights ● Webinar

Toward carbon-free energy

What is causing most CO2 emissions in industrial operations and how to remove fossil emissions from industrial operations? In this episode we will discuss how Valmet and Gasum are collaborating to move toward carbon free energy and other carbon lowering initiatives their companies are taking.

Insights ● Podcast

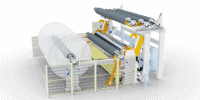

OptiReels without center drives

OptiReel Pope and Linear without center drives are Valmet’s standard reels. They provide just the right level of reeling technology required by grades and operations with less demanding reeling conditions - especially suitable for containerboard and uncoated fine paper grades.

Board and paper

IntelliReel

The IntelliReel structure enables easy control over the reeling process. It lets to wind a paper precisely, repeatably, efficiently and safely. A uniform parent roll is obtained and ready for converting operations by the end of reeling process. IntelliReel benefits include: controlled nip throughout winding process, minimized winding defects and sheet losses, easy process control, safe and minimized maintenance and it can be a tailor made solution. In the optimum parent roll structure building the purpose of nip relieving is to reduce the excessive weight of the spool and thus control the nip load between the spool and reel drum.

Board and paper

Slitter management

Slitter management at board and paper machines was developed by Valmet to help our customers overcome winder problems such as poor slitting equipment condition, poor quality blades and bands, dull blades and bands, hand injuries and insufficient operator slitting process knowledge and abilities. Valmet Slitter management brings slitting best practices to your winder. Our services and technology include state-of-the-art blade design and materials, sharpness techniques, safe and easy slitter changes, and comprehensive OEM slitter section training.

Services

OptiWin Drum two-drum base winder

The OptiWin two-drum base winder is renowned for its extreme robustness and utmost reliability. It is ideal for grades that tolerate a high nip loads, such as linerboard, corrugating medium, uncoated wood-free, and DIP news. The level of automation is high to reach high capacity.

Board and paper