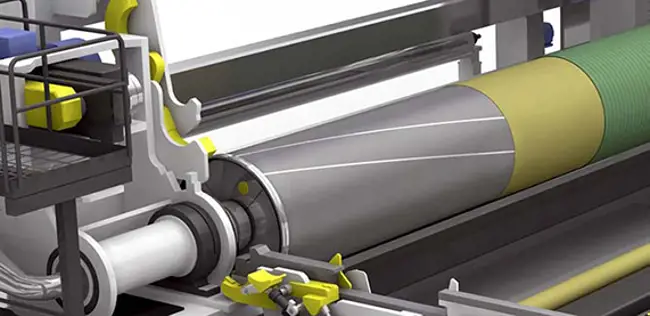

Roll covers for pulp drying

Long running periods with Valmet’s roll covers

Pulp drying machines are harsh chemical environments for roll covers. Reliable roll covers are needed to reach long running periods between planned shutdowns and to ensure long fabric lifetimes. Valmet’s roll covers are running and proving their performance each day in largest pulp dryers in the world.

Long running periods to fit planned shutdowns

Longer maintenance intervals

Improved dewatering

The right, modern roll cover solution brings more benefits

Valmet has an excellent selection of rubber covers providing reliable and cost efficient operation. For cases in which traditional approach no longer provides optimal wear resistance, there are more modern materials, such as composite or polyurethane covers available for the pulp drying process. Compared to customary rubber compounds, these modern roll cover materials bring clear, long-term benefits in longer running periods and improved dewatering.

Valmet’s roll covers such as rubber cover Press Roll Cover PT with improved wear resistance, Press Roll Cover VT, a tough composite cover that provides longer cover life, and hard coating Press Roll Cover TM are recommended for the most demanding conditions.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

CONTACT US

Explore our roll cover products from interactive demo

By exploring this roll cover application tool you can easily see different cover options for your pulp drying line.

Start exploringiRoll technology for controlling nips

Valmet roll covers can be used with iRoll – the most versatile and sensitive online profile measurement tool in the industry. This technology provides real-time insights into the pulp drying process, making it possible to adjust and optimize performance to the highest level. iRoll applications can be for optimizing press nips, reducing web breaks in pulp dryer with tension profile measurement or improving drying section performance with iRoll Temperature.

Valmet's latest Industrial Internet offering combines process technologies, services and automation to provide applications and services to improve the reliability and performance of your processes. Customers can also have remote monitoring and real-time support from Valmet’s experts through the Performance Centers.

Close to you through 26 roll service centers

Our global roll workshop network around the world ensures professionals can easily carry out roll cover inspections; perform onsite coating, patching and repair services; and provide application support and general troubleshooting in your location. We also offer support ranging from grinding, recovering, and servicing rolls, to complete roll service management

References and articles