Extensive possibilities to develop your tissue products

Advantage ViscoNip Press

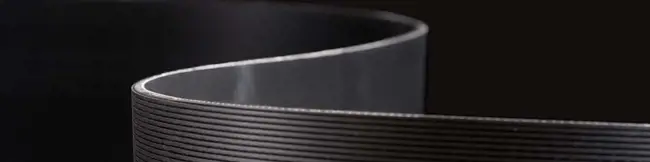

The new standard for wet pressing technology. A flexible liquid filled press body gives the Advantage™ ViscoNip® press the unique ability to adapt to the Yankee dryer shell.

ENERGY SAVINGS

Significant drying energy savings > 20%

High press dryness

UNIFORMITY

Perfect nip profiles in cross machine direction

Soft loading element, adaptive to conditions of other machine components

Many positive product and production spin-off effects; Quality and efficiency

FLEXIBILITY

High production capacity

Adjustable nip load for bulk increase and energy savings

Replacing a traditional shoe press with the unique ViscoNip press can really make a difference. Together we can explore how to increase speed, lower your energy consumption and achieve better uniformity.

Get in touch todayRemarkable results for rebuilds

The patented Advantage ViscoNip technology is an excellent option for tissue machine rebuilds. With 100 pieces sold, the Valmet Advantage™ ViscoNip® press is a trusted example. Tissue makers around the world are reporting enhanced product quality, increased flexibility and runnability, along with cost reductions, lower energy consumption, and savings from fiber conservation.

In cases where the Yankee dryer might be limited to a nip load of 90 kN/m, which is common in many existing machines, the ViscoNip press can be a suitable option as remarkable increase in dryness is achieved right away already at 90 kN/m compared to a Suction Press Roll.

Talk to us and we can tell you more about how a rebuild could be possible for your mill. We also have many examples of successful installations around the world to share.

Explore more!

Download the digital brochure available in several languages to learn more details about this unique product.

BrochureTissue makers share their stories

What is one hundred?

Together with our customers we have reached a milestone, something worth celebrating. We celebrate efficiency measured in energy, fiber and emission all over the world.

So, what is one hundred?

For us, it’s celebrating the 100th Valmet Advantage ViscoNip press by saying thank you, times one hundred.

Product flexibility and fiber saving possibilities

A flexible liquid filled press body gives the Advantage ViscoNip press the unique ability to adapt to the Yankee dryer shell. The uniform cross machine direction operates over a wide range of linear loads, which opens for extensive possibilities to develop your products.

- Low linear load provides highest possible bulk and softness. It also allows for fiber savings

- High linear load improves energy and production efficiency

Uniform pressing conditions

The uniformity in pressing conditions can be seen in the remarkably flat cross machine dryness profile generated which also is visible in the very even moisture profiles achieved in the parent roll. These even profiles also improve machine runnability and reduce the risk of chatter marks on the Yankee dryer.

Saving potentials

With the Advantage ViscoNip Press your can lower the environmental footprint in your tissue production by saving fiber, energy and reducing CO2. Contact us and we can discuss more in depth what it could mean for your mill.

Contact us

|

Fiber |

CO2 |

Energy |

Real-time monitor for performance and health

Valmet Industrial Internet offers a wide portfolio of applications to monitor the performance and health of your ViscoNip. Automatic alarms can be sent to the Valmet performance centeres located in different locations around the world with 24 hours remote support. For easy overview we can create customized dashboards and diagnostic applications. Reliability allows for improved maintenance planning and using the predictive technology the operators can potentially avoid production losses.

> Learn more about our Industrial Internet solutions for tissue

Q&A

Q: What is the Advantage ViscoNip press?

A: It is a press used in the tissue making process that has a similar base to a shoe press.

Q: How is the Advantage ViscoNip different from a “normal” shoe press?

A: An “ordinary” shoe press has a stiff metal shoe resulting in challenges with follow the deformation of the Yankee. The big difference with the ViscoNip press is in the loading system. When running the machine, the loading element is soft and flexible and can therefore adapt to the Yankee shell. This gives uniformity and creates a solid base for good production.

Q: As a tissue producer, can I replace my current shoe press with a ViscoNip press?

A: Yes you can, regardless if you have a Valmet produced machine or not.

Q: Is this a “one version fits all machines” kind of product?

A: We have designed different loading elements depending on the machine type. For example, in our Advantage DCT200 machines we have an optimized design for high linear load up to 150kn/min. For rebuilds we are sometimes limited to a lower linear load and in those cases, we have another optimized design.

Q: How should I take care of my ViscoNip press?

A: You should have a good maintenance plan to ensure that it continues to perform at maximum capacity. Our recommendation is to work in a preventive way to avoid unexpected shutdowns.

One example is that we have trained ViscoNip specialists in all areas that can travel to mill sites.

We also have a test to check the condition of the hydraulic system, from automation to roll to make sure all components are in mint condition.

Q: How much energy could I save with the Advantage ViscoNip press?

A: Customer have seen significant drying energy savings of more than 20%