Flow control for compressor stations

Improving reliability and productivity of your process

Valmet has a complete line of valves and flow control services designed to protect and optimize the compressor station process so operators can focus more on revenue and less on the fear of downtime, unsafe conditions or regulatory nonconformance.

Noise and vibration reduction

Increased throughput and efficiency

Improved plant safety

Lower maintenance costs

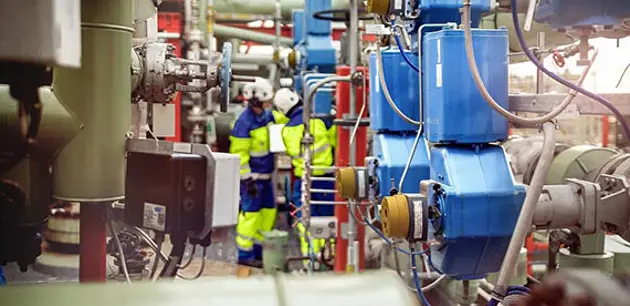

Reliable valves and services for compressor stations

Harsh conditions for safety and operation-critical valves

Even though compressor stations are often unmanned, safety is the most important consideration and should be the focal point of every decision surrounding the construction and operation of a compressor station. Safety control systems and emergency shutdown mechanisms must be multi-layered and ready to instantly detect and react to leaks, fires, or unstable operating conditions, including pressure surges in order to prevent safety or environmental dangers and to protect critical infrastructure.

High differential pressure of gases coming into the compressor station at low pressure and leaving at high pressures can create considerable noise and vibration. Noise must be checked to comply with regulations, while vibration must be mitigated to protect critical infrastructure and prevent premature wear on valves and instrumentation built into the piping structure.

Minor inefficiencies over the length of a pipeline will soon compound resulting in considerable potential revenue loss. The valves used in compressor station service can make the difference. Of course they must be reliable and withstand harsh process conditions, and at the same time offer a high degree of accuracy and fast stroking speeds in order to maximize throughput at the safest possible volume without breaking the surge line.

Improved valve performance equals improved efficiency

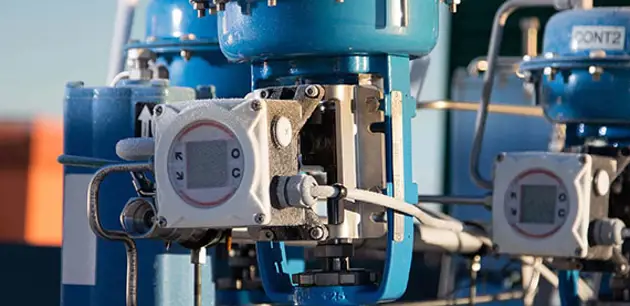

Valmet has a complete line of valves, actuators, positioners and communication technology designed to provide the best possible protection and efficiency. As a single-source supplier of these assemblies we engineer them together to optimize efficiency and take full responsibility for their performance. Produced in an ISO 9001 facility we test 100% of our products before they leave our doors to ensure they meet important standards including NACE, CRN, ATEX, GOST and many others.

Q-Trim™ noise attenuating valves from Valmet prevent noise before it starts. With the ability to reduce noise by up to 30 dB versus standard valves Q-Trim will make it easier to comply with noise regulations while also helping to prolong the life of critical infrastructure surrounding the valve including capital expense equipment. Additionally, Valmet's valves include self-cleaning valve trim that will prevent buildup in the valve. This will ensure long-lived valve accuracy and prevent unscheduled shutdowns or maintenance.

The entire valve assembly from Valmet is designed to increase efficiency. Tight bi-directional shut-off features within the valve and superior seat design reduce leaking to prevent loss and keep operators in compliance with regulatory standards. Valmet actuators provide high torque and stroking speed in a relatively lightweight package to reduce stress on the piping structure. Finally, our valve positioners and communication technologies will help to optimize the flow of gas through the compressor station allowing operators to run at peak volume for extended periods.

Process protection and efficiency

Valmet helps to protect and optimize the compressor station process so operators can focus more on revenue and less on the fear of downtime, unsafe conditions or regulatory nonconformance. Our full line of assemblies and global service mean that we are never too far away.

Flow control solutions and services for compressor stations

Read more about our solutions for gas processing