Flow control for steel mills

Valmet’s valve solutions for the steel industry cover every stage of steel production, from ironmaking to steelmaking, continuous casting and rolling, and power plant, oxygen plant and other supporting process areas. Whatever your application, our products deliver proven reliable technology and lasting cost-effective performance.

Availability

Improved plant performance

Reduced risks

Steel mill applications

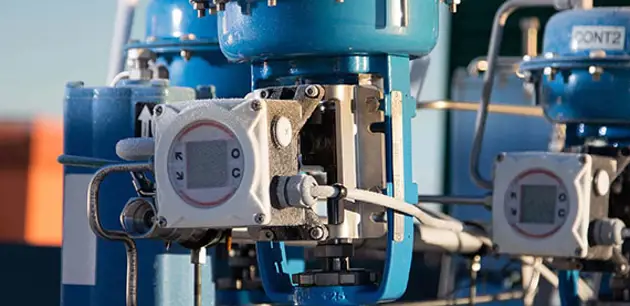

At every step of the steelmaking process, you need safe and reliable valves to handle industrial gasses, steam, water, lime and other process media. We offer a portfolio of products and services based on our customer’s needs, ranging from standard to demanding applications.

Steel mill’s by-product gases – such as coke gas, converter gas and blast furnace gas – are often used as a source of energy at the steel mill. Valves in these services must operate at high temperatures and withstand the impurities that are often present. Many of the process air and water services can be described as standard applications with little if any challenge. However, when you operate a cooling or descaling water application at the rolling mill, for example, you must take into account several challenges when selecting the most suitable flow control product.

Valmet offers a wide range of valves, pumps and flow control solutions from standard steel applications to the most demanding ones.

Steel mills, like any large-scale industrial complex, face a wide range of challenges. Imagine a typical day: Targets are met until one of your valves starts performing poorly, impacting production. Your maintenance department takes immediate action to repair the device and resume production as quickly as possible.

Valmet services help customers across the globe prevent such valve issues, increase availability, reduce risks and improve plant performance. Our digital tools give you a complete view of how your process and valves are performing by monitoring the condition and pinpointing underperformance before it causes downtime. We also support you in determining when and how to maintain valves, selecting spare parts, planning shutdowns and seizing opportunities to improve valve and process performance.

Downloads

Valves, pumps, valve automation and services for steel

Flow control for different applications in mining and minerals processing